Proto21 and Myata achieve a Guinness World Record for the world’s largest 3D-printed structure by volume

Dubai-based Proto21 3D Printing and Myata Platinum restaurant have set a new Guinness World Record for the world’s largest 3D-printed structure by volume. The feat was achieved on February 25, 2025, in Dubai, with a 13.75 cubic-metre structure that showcases the cutting-edge potential of 3D printing in architecture.

The monumental creation spans approximately 100 square metres and includes various features, such as an integrated entrance area, a cave, and wall facades. Among its most impressive elements is a staircase facade that soars to 8.6 metres. The entire structure measures 15.73 metres in length and 6.78 metres in width.

“This world record is not only a milestone in Proto21’s growth but also an important milestone in the evolution of 3D printing technology,” said Arkam, CEO of Proto21. “The precision and scale we’ve reached represent a new frontier for what can be accomplished in the realm of construction.”

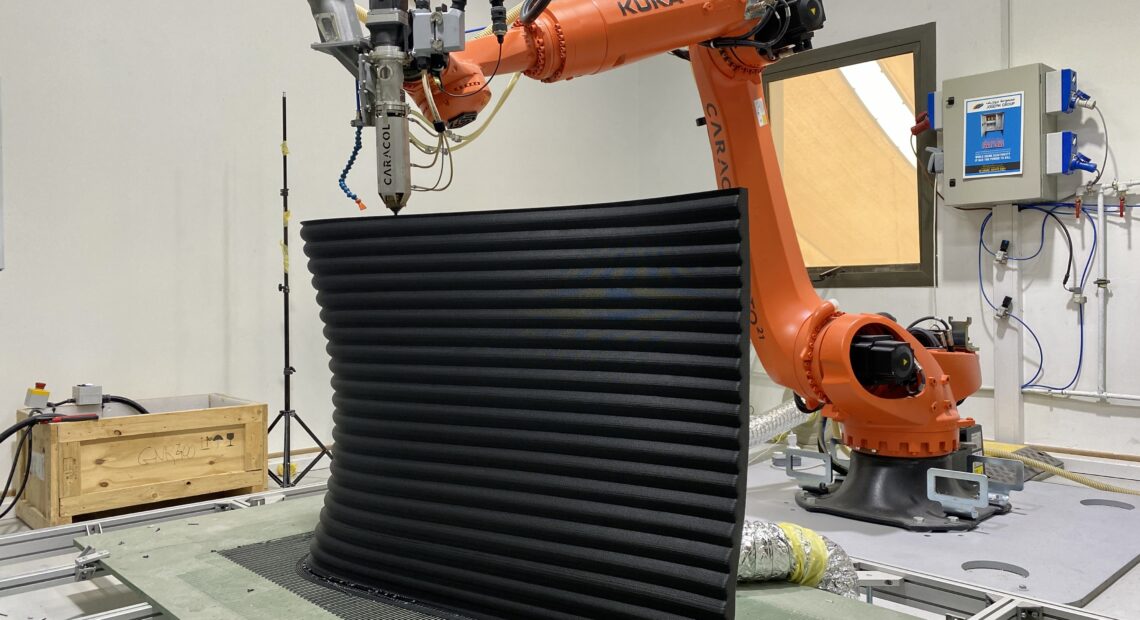

Proto21’s 3D printing facility, which houses 150 FDM (Fused Deposition Modelling) machines, played a key role in bringing this world record to life. Printers worked in unison, producing multiple parts simultaneously while optimising material usage and minimising downtime.

The Myata restaurant is home to this record-breaking structure, one of 23 large, amorphous 3D-printed designs that make up the restaurant’s interior and exterior facades. The restaurant’s entire design, drawing inspiration from the fluid topography of sand canyons, creates an immersive experience for diners. The restaurant features not only facades but also unique elements such as VIP rooms, caves, counters, and planters, all created using 3D printing technology. The structures are painted with a sand-texture finish, giving them a natural, rock-like appearance that blends cutting-edge technology with organic aesthetics.

The 3D designers at Proto21 applied intricate, sedimentary designs to each architectural plane, ensuring that each piece was unique. This deliberate focus on natural patterns exemplifies the company’s belief that nature is the world’s most brilliant architect, with rivers carving valleys and wind sculpting mountains. As a result, the designs at Myata replicate the beauty and unpredictability of the natural world.

“The sheer complexity of this project makes it one-of-a-kind,” said Pir Arkam, Proto21’s founder. “92% of the pieces are unique, meaning almost no repeats. This is something traditional manufacturing cannot achieve.”

The restaurant uses soft amber lighting to illuminate the space and enhance the complex canyon topography, tables, and bar counters. The lighting, combined with various art effects, adds to the immersive atmosphere, highlighting everything from the clouds of steam from a hookah to the hypnotic halo effects in different areas of the space. The entrance area, designed with the ‘funnel principle’ in mind, narrows as visitors approach, guiding them into a larger, cave-like lounge that creates a sense of mystery and anticipation.

Proto21’s scope of work for the project included 3D designing, structural calculations, 3D printing, assembly, finishing, painting, and installation, offering a complete turnkey solution. The project’s complexity took more than six months to complete.

The numbers behind the project are impressive: over 1,190 square metres of 3D printed area, 38 cubic metres of printed volume, more than 21,700 individual parts, 158 3D printers, and a total of over 160,000 hours of 3D printing. The demand for materials was so high that Proto21 had to call in every supplier in the UAE to meet the project’s requirements. The team used various materials, including PLA, PETg, and PPGF (Polypropylene Glass fibre), to withstand the harsh UAE summer temperatures.

“This project redefines what’s possible with 3D printing technology,” said Arkam. “It proves that 3D printing is no longer just an experimental technology but a scalable, game-changing solution for commercial applications.”

Image: 3D printing robotic arm system at Proto21 3D Printing. Credit: Proto21 3D Printing

Last Updated on 2 weeks by Arnold Pinto