Leap 71 achieves milestone with Aerospike rocket engine test

Engine was designed autonomously

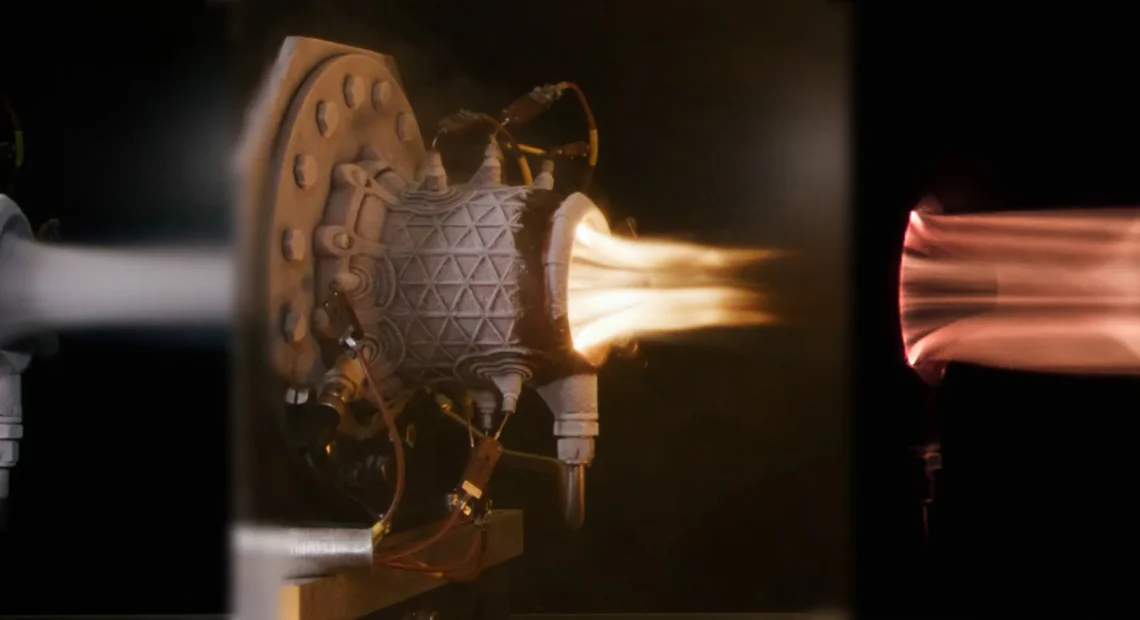

Leap 71, a computational engineering company based in Dubai, UAE, has successfully hot-fired one of the most advanced rocket engines ever created—a cutting-edge Aerospike engine generating 5,000 Newtons (1,100 lb) of thrust.

This remarkable feat was made possible using cryogenic liquid oxygen and kerosene as propellants. The engine, designed autonomously by Leap 71’s sophisticated large computational engineering model, Noyron, marks a significant milestone in rocket propulsion technology.

The successful test positions Leap 71 among a select group of teams that have tackled the complex challenges associated with Aerospike engines over the past three decades. These engines, known for their compact design and enhanced efficiency, operate without the traditional bell-shaped nozzle. Instead, they employ a central spike within a toroidal combustion chamber, which improves performance across varying atmospheric pressures, including the harsh space environment.

Innovative engineering and design

Developed in weeks, the Aerospike engine was manufactured as a monolithic piece of copper using state-of-the-art industrial 3D printing techniques. The entire process underscored the potential of Noyron’s computational AI, which facilitated rapid prototyping and iteration. Once fabricated, the engine was put through its paces on the test stand, where it operated successfully on its first attempt. This impressive outcome showcases the efficacy of Leap 71’s methodologies.

However, the design of the Aerospike engine is not without its challenges. The spike, which plays a critical role in the engine’s operation, is subjected to extreme conditions, surrounded by exhaust gases reaching 3,500ºC. Intricate cooling systems were implemented to manage this intense heat. Cryogenic oxygen flows through cooling channels to maintain the spike’s integrity while the chamber’s exterior is cooled using kerosene fuel.

Leadership insights

Josefine Lissner, CEO and Co-Founder of Leap 71, expressed her enthusiasm about the test results. “We were able to extend Noyron’s physics to address the unique complexities of this engine type. The success of this test is a testament to our technology and validates our physics-driven approach to computational AI,” she stated.

Co-founder Lin Kayser echoed this sentiment, highlighting the underutilisation of Aerospike engines in current space access technologies. “Despite their advantages, Aerospikes have yet to see widespread application in aerospace. Our goal is to change that. With Noyron, we can significantly reduce the time needed for re-engineering and quickly converge on optimal designs,” he said.

Collaborative efforts

The Aerospike’s manufacturing process involved collaboration with key industrial partners. Aconity3D used a laser powder bed fusion technique to produce the engine from an advanced aerospace copper alloy (CuCrZr). After printing, Solukon thoroughly cleaned the engine and heat-treated it at the Fraunhofer Institute for Laser Technology. The University of Sheffield’s Race 2 Space Team provided additional support, preparing the engine for testing and assisting during the test campaign.

The successful hot-firing of the Aerospike took place on December 18, 2024, at Airborne Engineering in Westcott, UK. This event was part of a campaign where Leap 71 aimed to test four engines over four consecutive days. The data collected from this testing will be crucial for further refinements of Noyron and the development of subsequent engine iterations. The company plans to continue testing throughout 2025, aiming to make Aerospike engines a viable option for spacecraft.

Hero image: Developed in weeks, the Aerospike engine was manufactured as a monolithic piece of copper using state-of-the-art industrial 3D printing techniques. Credit: Leap 71