Paradigm 3D keeps the Middle East aerospace sector in flight

New Dubai facility benchmarks UAE as a world-class additive manufacturing hub

With three global supercarriers – Emirates, Qatar Airways, and Etihad Airways – all operating from home turf hubs in the Middle East and as the hydrocarbon-rich region grows its aviation and Industry 4.0 capabilities exponentially, Dubai-headquartered Paradigm 3D is in pole position to fulfil the fast-rising regional demand for internationally certified 3D printed additive parts for hi-tech sectors: principally, aerospace.

Paradigm 3D formally inaugurated its advanced 3D printing production facility at Jebel Ali Industrial Area on the outskirts of Dubai City on September 21, 2023.

Located within sight of the gleaming Burj Khalifa skyscraper and set up at a cost of a little over AED20 million ($5.43 million), the 10,750sqft facility is the first factory in the Middle East and Africa region that is fully certified to 3D print parts and components for the global aerospace sector and other industries.

From the UAE

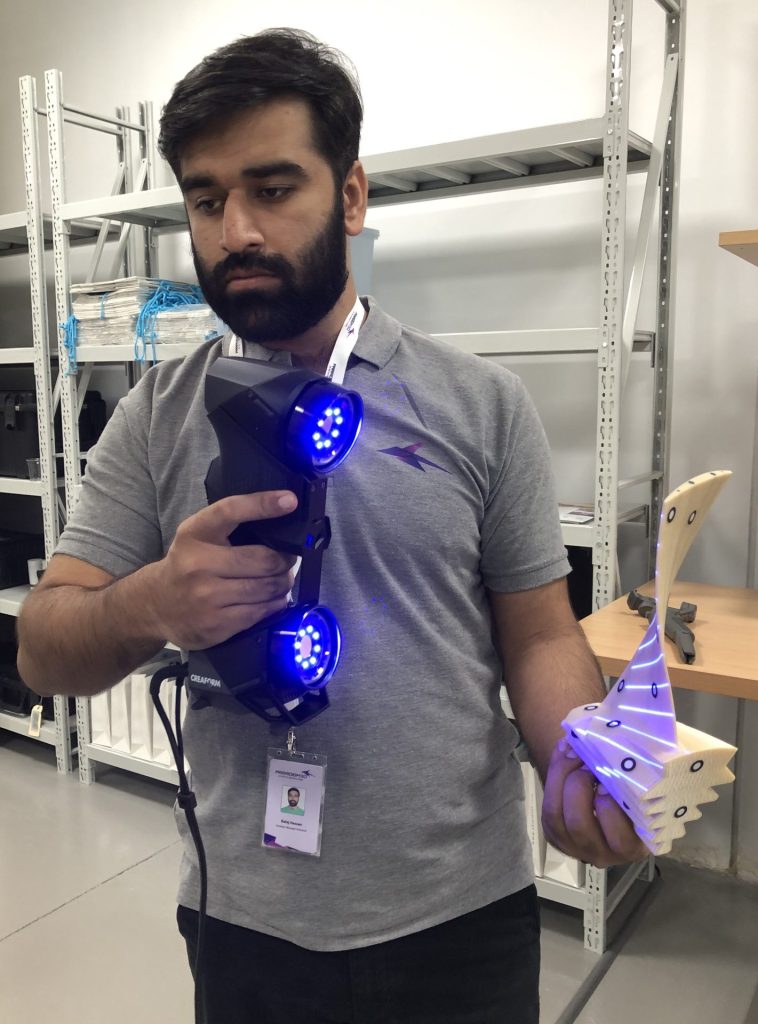

Benchmarking the UAE as a world-class hub for the fast-growing additive manufacturing vertical, the unassuming-to-look-at facility deploys advanced Stratasys FDM 3D printers for industrial additive and metal work.

Stratasys’ FDM (fused depiction modelling) 3D printers turn CAD files into durable parts that are tough enough to be used as advanced conceptual models, functional prototypes, manufacturing tools, and production parts.

The FDM 3D printers use a range of engineering-grade and high-performance thermoplastics to manufacture functional parts directly from digital data.

The new Paradigm 3D facility’s production capacity averages 2,000 additively manufactured parts annually and is projected to increase to 20,000 units annually within 10 years.

Although Paradigm 3D can produce various 3D parts for multiple industries, the company focuses its core production on the regional aerospace sector.

The company specialises in 3D printing of aircraft cabin parts, including seats, tray tables, footrests, lavatories, electronic cooling ducts, environment control system ducting, wire guides, filter boxes, micro vanes, gaskets, component connectors, air intake manifolds, etc.

Stratasys expertise

With its corporate headquarters in Rehovot, Israel and Eden Prairie, Minnesota, United States, Stratasys is a global leader in additive technology solutions for aerospace, automotive, consumer products, design, education, and healthcare.

Paradigm 3D’s business model relies on twin strategic partnerships involving Stratasys’ Dubai-based platinum partner, The Design to Manufacturing Company (theD2Mco), and Riga, Latvia-based certified aerospace production company, AM Craft, which holds an EASA Production Organization Approval (POA).

As contracted, theD2Mco has installed several advanced Stratasys industrial 3D printers at the new facility and is tasked with providing aftersales support and service.

At the same time, AM Craft has enabled Paradigm 3D to become the first facility in the Middle East capable of producing 3D-printed parts that adhere to the stringent aerospace-specific EASA Part 21G regulation.

Paradigm 3D is also the first 3D manufacturing site outside the European Union under AM Craft’s certification and technology perspectives.

AM Craft also supports Paradigm 3D to offer its bespoke regional manufacturing capabilities to regional aircraft operators, including airlines and other fixed-wing and rotary aircraft operators.

National initiative

Kyriakos Papantoniou, Group Executive Director at theD2Mco and Director at Paradigm 3D, said: “We are committed to collaborating with Stratasys in supporting the UAE government’s vision for its manufacturing sector through initiatives such as Operation 300bn.

Operation 300bn aims to raise the industrial sector’s contribution to the UAE’s GDP from AED133 billion ($31.14 billion) to AED300 billion ($81.52 billion) by 2031.

“The use of Stratasys 3D printers for primary production applications sets the facility apart from others in the region, enabling it to confidently serve customers’ needs in highly regulated industries such as aviation. We see clear potential for the new plant to serve the UAE market and the entire region,” Papantoniou added.

Jānis Jātnieks, founder and CEO of AM Craft, stated: “Airlines operate globally, and the Paradigm 3D facility will enable both regional and global aerospace companies to benefit from decentralised and on-demand manufacturing.

“We are assisting Paradigm 3D to enable them to become a one-stop-shop for designing, manufacturing and postprocessing certified aircraft components exactly when and where they are needed for immediate installation on aircraft,” Jātnieks said.

‘Core growth enabler’

Muhammad Jumma, President of Paradigm 3D, said: “We see additive manufacturing as a core growth enabler for manufacturing in the region. The UAE’s appetite for innovation and the government’s support for projects that leverage industrial 3D printing means the country is perfectly positioned to be a hub for a real digital manufacturing revolution.

“Proving our abilities in the highly regulated aviation sector will validate the numerous advantages of 3D printing. It will enable us to expand into parallel sectors, such as oil & gas and other industrial applications,” Jumma added.

Worldwide, leading aircraft and cabin interior product manufacturers, including Boeing, Collins Aerospace, BAE Systems, Airbus, Diehl Aviation, Boom Supersonic, Dassault Aviation, and Safran Seats, use additive manufacturing systems from Stratasys.

Meeting the demand

Andreas Langfeld, Stratasys EMEA President, said: “What makes Paradigm 3D’s facility unique is that it is the only 3D printing service provider in the Middle East certified to produce 3D-printed parts for private and airlines’ aircraft.

“Having this capability in Dubai reduces the lead time for replacement parts by weeks, possibly even months, helping airlines keep their planes in operation more predictably.

“This will reduce operational costs, particularly around logistics, and the environmental impact of transporting these spare parts,” Langfeld noted.

Justin Cunningham, Senior Regional Marketing Manager, North, East and Wider EMEA at Stratasys, said the new Paradigm 3D production plant is a game-changer for the UAE and the broader Middle East and Africa region as the new facility can drastically reduce the downtime that aviation operators typically face while waiting to replace worn out or outdated parts, while also substantially reducing parts’ production and supply chain costs.

Godfather of 3D printing

Scott Crump, Co-Founder of Stratasys, attended the official opening of the Paradigm 3D facility on September 21, along with Dana Goldfinca, Latvia’s Ambassador to the UAE, and other dignitaries.

Crump is globally renowned as the godfather of 3D printing for his revolutionary and patented invention, fused deposition modelling (FDM), synonymous with contemporary 3D printing.

Featured image: Paradigm 3D stakeholders and dignitaries at the new facility’s opening ceremony on September 21, 2023. Image: Arnold Pinto

Last Updated on 1 year by Arnold Pinto